The business of sustainability continues to evolve rapidly. Here are the most important changes to expect in the coming year.

By: Elsa Wenzel

View the original article here

With COP28 recent in the rearview mirror, 2024 represents a clear and critical inflection point for confronting the climate crisis. New rules in the European Union and in California, the world’s fifth-largest economy, will change how global businesses report risks, purchase energy and manage supply chains. The effects of the Inflation Reduction Act in the U.S. are still emerging: 175 nations are hashing out the first global treaty to end plastic waste.

Below are some defining moments that will drive change in the business of sustainability in the coming year.

Carbon

Expected U.S. SEC climate-related disclosures in April will require companies to report their GHG emissions.

The U.S. Office of Fossil Energy and Carbon Management, part of the Department of Energy, announces winners in February of its carbon dioxide removal purchase pilot prize and will publish details for corporate sustainability teams’ own carbon removal due-diligence processes.

New guidance from the Science Based Targets initiative on the use of environmental attribute certificates, including carbon credits, in decarbonization goals should come out by summer.

By the end of 2024, companies subject to California’s new Climate Corporate Data Accountability Act (SB253) will need to establish processes for auditing their 2025 emissions ahead of 2026 reporting.

Finance and ESG

A new proposal may emerge in the spring from the U.S. Securities and Exchange Commission (SEC), after it again delayed its climate change disclosure rulemaking.

Changes to the EU’s Sustainable Finance Disclosure Regulation (SFDR) 2.0 are likely following a September 2023 review.

Sometime in 2024, the U.S. Federal Trade Commission’s updated Green Guides are expected to update what “greenwashing” means in business and marketing.

Nature and biodiversity

The EU’s Corporate Sustainability Reporting Directive (CSRD), requiring companies to disclose their risks from environmental and social factors, takes effect Jan. 1.

COP16, the 16th Conference of the Parties to the Convention on Biological Diversity, will take place in Colombia from Oct. 21 to Nov. 1.

Revised or updated National Biodiversity Strategies and Action Plans (NBSAPs), including national targets, are due by COP16.

By Dec. 30, operators and traders must prove deforestation-free sourcing for targeted commodities in the EU market. That’s the EU Deforestation Regulation (EUDR) compliance deadline.

Food and agriculture

The EU CSRD goes into effect as 2024 begins, influencing supply chain impact disclosure and bringing new evidence of deforestation.

Supply chains risk disruptions if the U.S. Farm Bill continues to stall in Washington in 2024.

Watch for the next steps from the hundreds of nations that signed sustainable food declarations at COP28.

Transport

The U.S. Departments’ of Treasury and Energy rules go into effect, barring vehicles with battery components from a “foreign entity of concern” from consumer tax credits.

The IRS expands its EV tax benefit by letting consumers choose between claiming a credit on their tax returns or using the credit to lower a car’s purchase price.

The ReFuelEU aviation initiative goes into effect Jan. 1 to advance sustainable aviation fuels (SAF) in the European Union. It also requires aircraft operators and EU airports to work towards emission reductions and to ensure a level playing field for airlines and airports.

In January, the EU extends its cap-and-trade Emissions Trading System (EU ETS) to regulate CO2 from large ships of any flag entering its ports.

The U.S. Department of Energy will release an updated Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation (GREET) model by March 1.

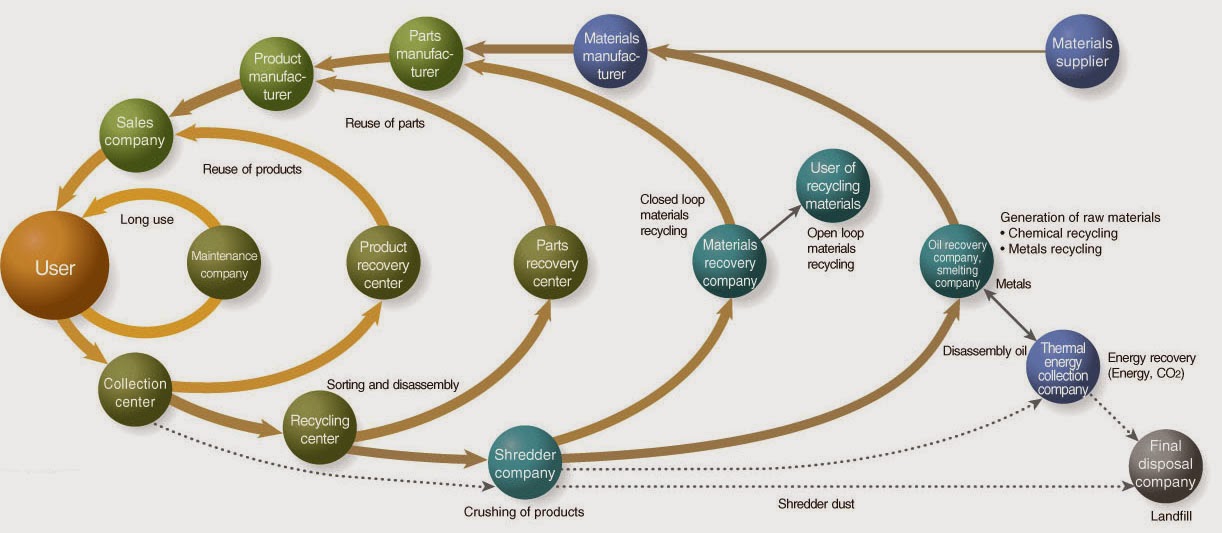

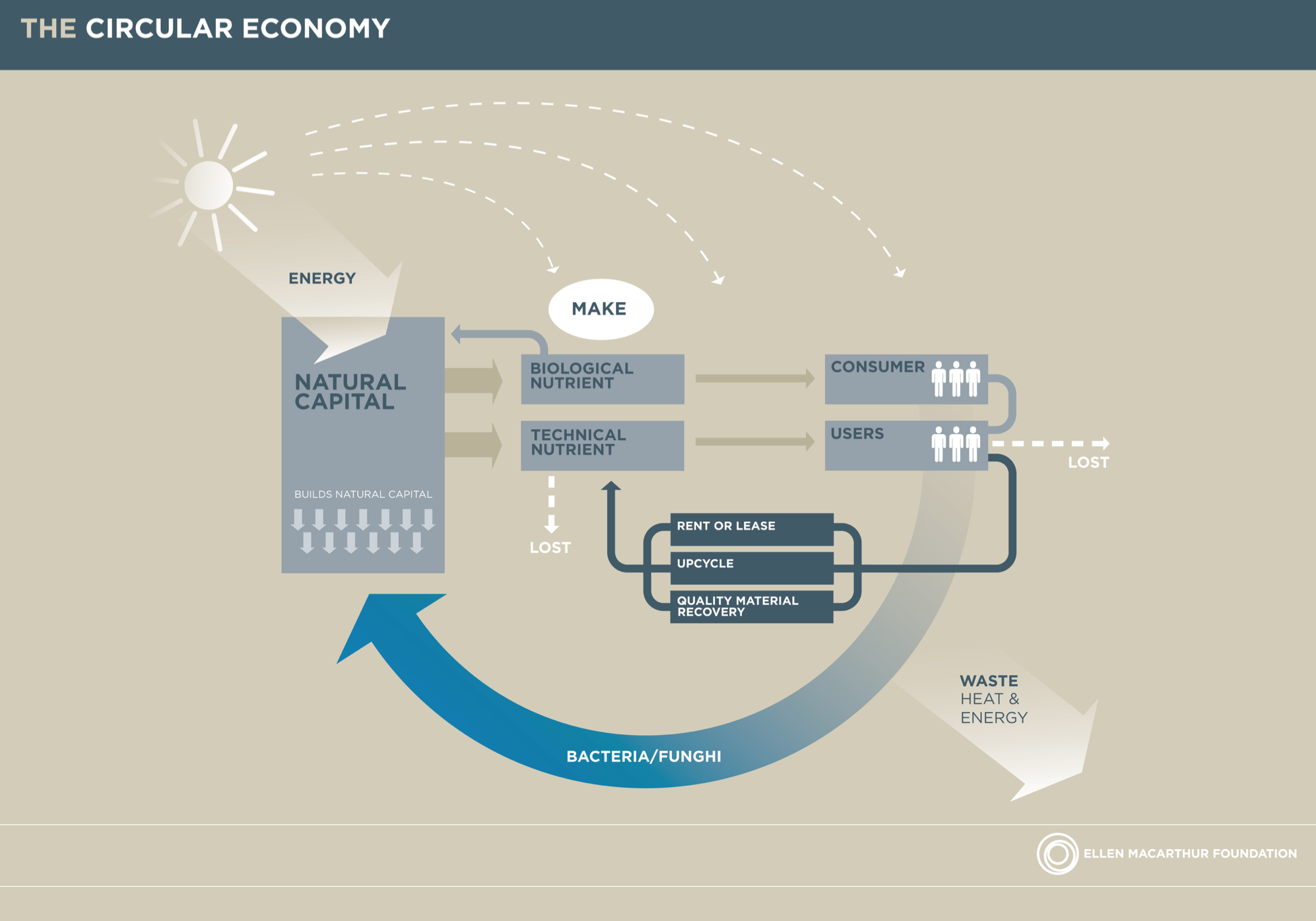

Circular economy

A hoped-for Global Plastics Treaty in 2024 moves forward with INC-4 meetings expected in April in Ottawa and INC-5 by November in Korea.

California, Maine, Oregon and Colorado are working on enforcement rules and other fine print for their new extended producer responsibility (EPR) packaging laws.

EU battery regulations are gradually being introduced, encouraging a circular economy for batteries.

Energy

At COP28, the U.S. announced new rules to cut methane emissions in oil and gas production, likely to change the energy cost equation. Watch for progress from 150 countries pledging two years ago to cut methane by 30 percent by 2030.

The Biden administration will be giving out $7 billion for its Regional Clean Hydrogen Hubs (H2Hubs).

2024 will be a watershed year for microgrids moment: Interconnection backlogs are creating a new value-add for microgrids, especially as the macrogrid can’t keep up with electricity demand.

Buildings

Watch the 28 countries agreeing at COP28 for “near-zero” buildings by 2030 through the Buildings Breakthrough.

Applications are due and funding will be announced for the EPA’s $27 billion Greenhouse Gas Reduction Fund, backing climate tech and moving money into communities.

Applications for the EPA’s Environmental Product Declaration (EPD) grants are due Jan. 16 from manufacturers.