It can also provide carbon-free heat for a wide variety of industrial processes

By Steven Moss

View the original article here.

Part of the Miraah soler thermal project in Oman. Credit: GlassPoint Solar

The industrial processes that underpin our global economy—manufacturing, fuel and chemical production, mining—are enormously complex and diverse. But they share one key input: they, as well as many others, require heat, and lots of it, which takes staggering amounts of fuel to produce. Heat and steam generation is critical to the global economy, but it’s also an overlooked and growing source of greenhouse gas (GHG) emissions.

The good news is that innovative solar technologies can produce steam at industrial scale—reducing emissions and, increasingly, cutting costs. And given the current climate outlook, it’s urgent that industry adopt these new technologies.

Despite enormous progress around the world to ramp up renewables and increase energy efficiency, global GHG emissions reached an all-time highin 2018. In a report released in January, the Rhodium Group found that even though renewable energy installations soared and coal plants shut down, carbon emissions in the U.S. rose sharply last year. Emissions from industry shot up 5.7 percent—more than in any other sector, including transportation and power generation. The authors of the Rhodium Group study concluded that despite increased efforts from policymakers and the business to tackle emissions, “the industrial sector is still almost entirely ignored.”

This must change, at the global level. Worldwide industry is responsible for a quarter of total emissions. And while those from transportation and residential segments are trending down, the International Energy Agency (IEA) projects that industrial emissions will grow some 24 percent by 2050.

As people around the world continue to transition from living off the land to moving to cities and buying and consuming more things, industrial activity will continue to increase—and the need to reduce corresponding emissions will become all the more urgent.

Credit: GlassPoint Solar

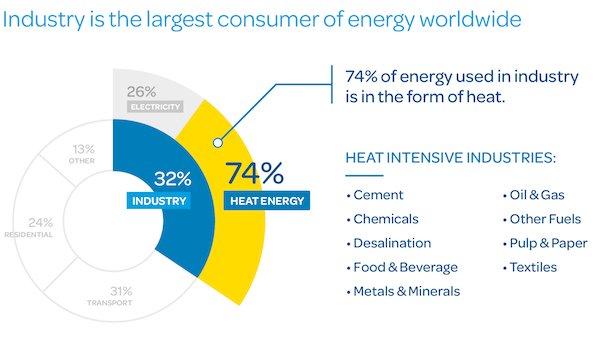

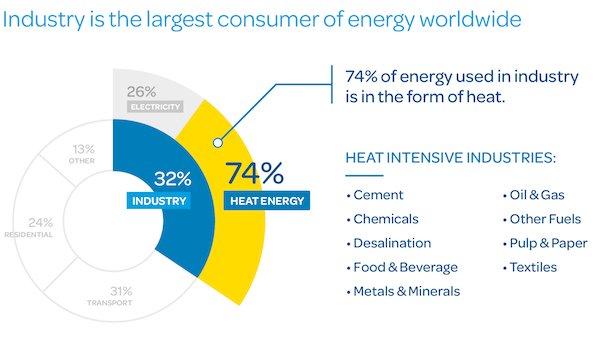

This brings us back to heat. Industry is the largest consumer of energy, and a surprising 74 percent of industrial energy is in the form of heat, mostly process steam. Solar steam—making the sun’s heat work for industry—is a largely unexplored but promising avenue for reducing emissions.

While photovoltaic (PV) panels that convert sunlight into electricity are more common, thermal solutions are what’s needed to meet industry’s growing demand for heat. In a solar thermal system, mirrors focus sunlight to intensify its heat and produce steam at the high temperatures needed for industry. Another key advantage is the ability to store the heat using simple, proven thermal energy storage in order to deliver steam 24 hours a day, just like a conventional fossil fuel plant. With the right technology, solar thermal can be a reliable, efficient and low-cost energy source for industrial steam generation.

So-called “enclosed trough technology” uses sunshine to produce zero-carbon steam. Credit: GlassPoint Solar.

For example, renewable process heat provider Sunvapor is partneringwith Horizon Nut to build a 50-kilowatt solar thermal installation at a pistachio processing facility in the Central Valley of California. The companies are working to expand solar steam production for food industry processes, such as pasteurization, drying and roasting.

In Oman and California, GlassPoint Solar is operating and developing some of the world’s largest solar projects for industry. GlassPoint’s greenhouse-enclosed mirrors track the sun throughout the day, focusing heat on pipes containing water. The concentrated sunlight boils the water to generate steam, which is used by Oman’s largest oil producer to extract oil from the ground. The capacity of GlassPoint’s Miraah plant, which can currently deliver 660 metric tons of steam every day, will top 1 gigawatt of solar thermal energy when completed. This same technology is also being deployed in California to reduce emissions from one of the country’s largest and oldest operating oilfields.

Meanwhile, to meet the needs of extremely high-temperature (800-1,000degreesC) industrial processes, the European Union is developing SOLPART, a research project to develop solar thermal energy that can be used to produce cement, lime and gypsum.

While fossil fuels remain the dominant source of heat for industry across all sectors and regions, industry is beginning to explore cleaner alternatives—and in some cases, industry is leveraging solar steam on a significant scale. As technology advances, more and more companies will find that switching to solar steam can simultaneously reduce costs and emissions, improving business operations while shrinking its carbon footprint.

When it comes to mitigating climate change, most attention has been directed to the things we see, buy, or use on a daily basis—the cars we drive, the food we eat, the power plants that keep our lights on. But behind all these activities is process heat, an emissions source that has been largely ignored.

Now we must turn our attention to industry—the sleeping giant of climate action. Process heat is an overlooked opportunity to slash GHG emissions, and solar technologies operating at the scale needed by industry are currently available. It’s time to embrace them and stop industrial heat from heating up our planet.