Written By: Paul A. DeCotis

View the original article here

Paul A. DeCotis, senior partner, Energy & Utilities at consultancy West Monroe, writes on key trends in the energy sector we will need to be on the lookout for in 2025.

In 2025, the energy and utilities sector will encounter both familiar challenges and new uncertainties. With a new presidential administration, potential regulatory changes could influence infrastructure investments and decarbonization efforts.

The industry is facing a significant surge in load demand driven by AI, data centres, and widespread electrification. To address this demand, utilities must enhance grid reliability and resilience while maintaining affordability and advancing clean energy goals. The market is also becoming more competitive as independent providers are looking to address emerging power generation, and infrastructure needs and clean energy goals.

At West Monroe, our Energy & Utilities practice has identified five key focus areas to help utilities navigate these changes and build a resilient, reliable, and inclusive energy future.

Trend 1: Load growth and T&D system needs

Energy demand is climbing rapidly due to AI, data centres, and increased electrification in buildings and transportation. Data centres alone require near-perfect reliability, adding pressure on the grid and necessitating substantial expansion in Transmission and Distribution (T&D) infrastructure.

As demand rises, distribution utilities must balance clean energy goals established by legislation or policy, with the need for accessible, affordable services. This accelerated growth increases complexity in load forecasting, complicating the balance between necessary system upgrades and equitable cost distribution.

Although new technologies aim to expand transmission capacity, the challenge lies in the pace of change and managing investments within the regulated industry structure.

The industry is also shifting from a collaborative stance to a more competitive landscape, with energy companies vying for growth opportunities across regions perhaps bypassing the local distribution utility.

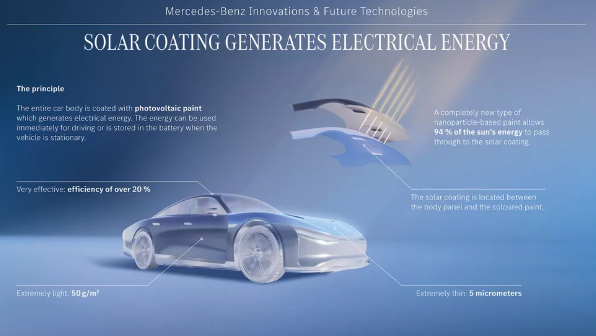

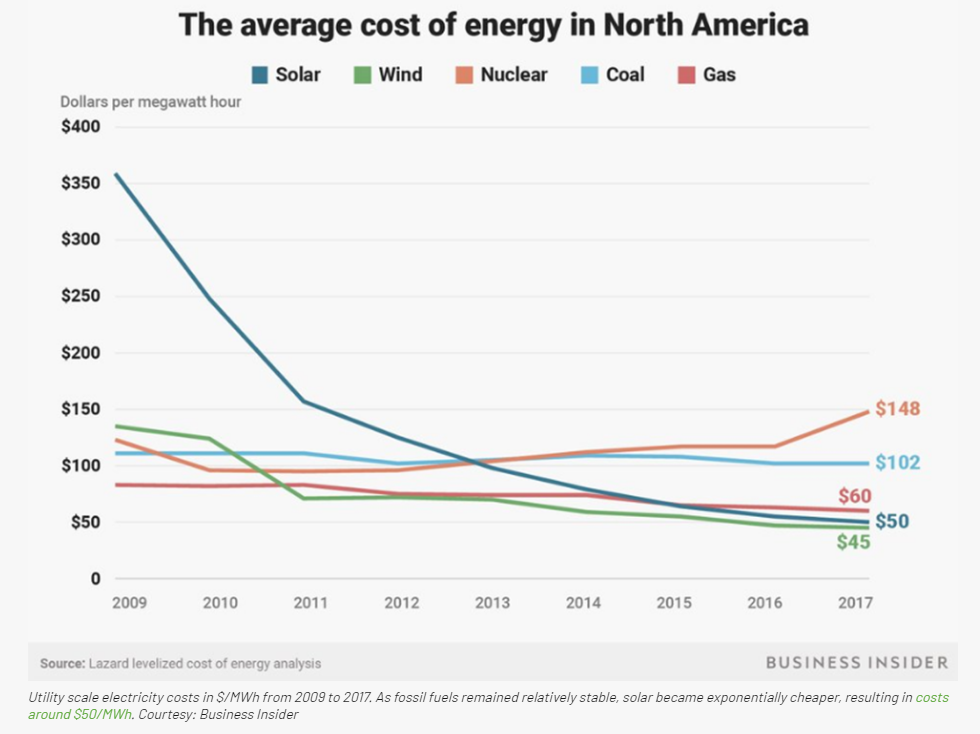

With load growth at this rapid rate, utilities and other companies will struggle to mobilise quickly enough to build the infrastructure needed to meet demand. Technology and data centre companies are already implementing on-site generation solutions, such as solar energy, and co-locating with natural gas and nuclear facilities to meet their energy needs.

Trend 2: Maintaining and enhancing safety and reliability

Maintaining grid reliability is becoming increasingly challenging due to aging infrastructure, extreme weather, and the integration of distributed and renewable energy sources.

Although the US electric grid ranks among the most reliable globally, significant investment is required to ensure ongoing safety, stability, and affordability.

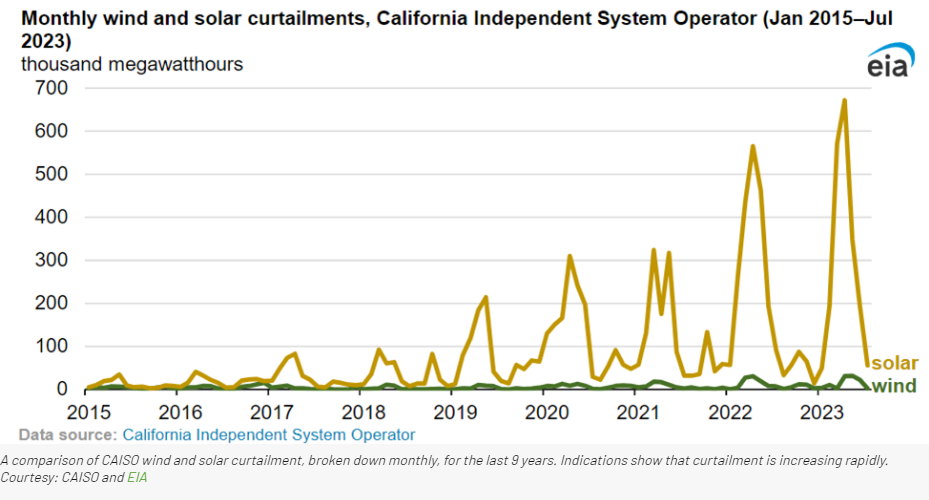

Unpredictable power demands from data centres and cryptocurrency miners further complicate supply management, while the intermittent nature of renewable sources can destabilise the grid, underscoring the need for robust planning and control systems.

To meet rising demands, utilities are exploring decentralised energy resources, microgrids, and remote grids.

However, financial constraints and supply chain issues can delay critical infrastructure upgrades, requiring utilities to prioritise spending strategically. Our energy future will not be solely electric, gas, solar, or wind; it will require a combination of resources working together to maintain safety, reliability, and achieve statewide decarbonisation goals.

Trend 3: Championing energy affordability

Regulators and utilities face complex, interconnected challenges as they transition to a lower-carbon economy.

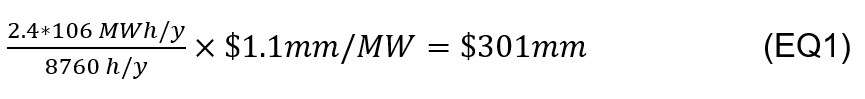

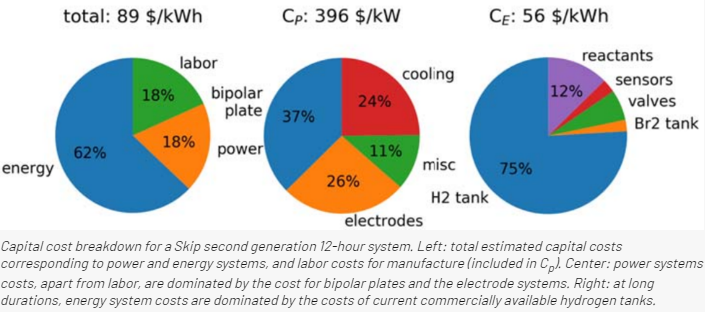

A critical focus is on identifying cost-effective investments for grid modernisation while keeping energy accessible and affordable for all customers. Utilities are tasked with securing trillions of dollars to upgrade the grid and support cleaner energy, amid rising capital costs and supply chain disruptions.

This situation is further complicated by the public perception of energy as a fundamental right, which can clash with the reality of private sector provision. As utilities refine their operating models and explore digital solutions to improve efficiency, the future of energy affordability remains uncertain, especially with equity concerns in play.

We must balance our clean energy ambitions with the need for a public policy approach that protects vulnerable populations while advancing environmental objectives.

Trend 4: Integrating AI into utility operations

AI, machine learning, and advanced analytics are transforming energy and utility operations, bringing powerful tools for optimisation and predictive insights.

From smart grid management to preventive maintenance, these technologies drive operational efficiency and elevate customer service. AI-driven analytics support regulatory compliance and offer more precise grid monitoring, helping utilities make better informed, data-driven decisions.

While AI can reduce operating costs, it’s not a substitute for the substantial investments required to meet growing electricity demands.

Additionally, the energy demand of AI itself necessitates careful oversight and transparency. Success relies on embedding AI into broader sustainability strategies, emphasising accessible tools and robust workforce training to drive effective change.

AI is the worst it is ever going to be right now—it is only going to improve from here. To thrive in this evolving landscape, organisations must invest in understanding and leveraging new andemerging technologies.

Trend 5: Strengthening cybersecurity to protect critical infrastructure

With rising threats in the energy sector, utilities and non-regulated private energy providers must adopt strong cyber resiliency measures.

The growing number of connected devices introduces vulnerabilities, where even a single compromised supply chain component can put entire systems at risk. Securing and monitoring equipment—and clearly understanding the ownership of critical components—are vital steps.

Utilities also face challenges with tight budgets and a cybersecurity skills gap. Preparing for geopolitical risks and policy changes will shape funding and priorities. As cloud tools expand and national databases for equipment manufacturers become available, utilities will need adaptable, proactive cybersecurity strategies for long-term success.

Cybersecurity in utilities isn’t static—it’s like preparing for a new type of storm. Just as we plan for hurricanes and wildfires, we must continually adapt our defenses to evolving threats.