Reviewed by: Olivia Frost

View the original article here

Energy is vital in the modern world, powering everything from transportation and production to communication and daily services.

As energy consumption continues to rise with digitalization, changes in mobility, and globalization, sophisticated grids have been developed to provide energy wherever and whenever needed. However, current and past energy consumption has come at a price.

The intensive use of fossil fuels and other limited resources has led to negative impacts, and the need for a more sustainable energy supply has become one of the biggest challenges facing humankind.

Renewable Energy Production on the Rise

Issues related to health, environment, economies, geopolitical risks, dependencies on limited resources, and advancements in sustainable energy production have prompted a reevaluation of energy policy.

According to the EMBER Global Electricity Review 2022, wind and solar reached a record 10% of global electricity in 2021, with all clean power totaling about 38% of the supply.

Renewable energy supply is an important step in reducing the CO2 footprint and mitigating climate change and the consequences caused by the phenomenon. Tapes are essential in helping wind and solar energy supply get into pole position in renewable energy production and grow even further.

Using these tapes in composite molding for wind turbine blades enables manufacturers to protect molds, tool surfaces, and blades, and also helps to reduce cost, effort, and labor time.

Saint-Gobain’s special PET or PTFE tapes, such as the CHR® M-Series or CHR 2255, are designed to withstand high temperatures and can be re-used multiple times, making them an efficient and sustainable solution for large-scale wind turbine production.

These continuous process improvements are crucial to making renewable energy production more efficient and cost-effective.

Using tapes with low CoF can help reduce the rework needed and improve downstream processes’ quality, making wind turbine manufacturing more efficient. The production of larger and more efficient wind turbines will play a significant role in increasing renewable energy capacity and reducing the reliance on fossil fuels.

Image Credit: ShutterStock/liyuhan

Renewable energy production is just one piece of the puzzle. To be consumed, renewable energy often needs to be transformed and transported.

Saint Gobain’s Kapton® and Nomex® tapes with high mechanical, electrical, temperature, and chemical resistance are crucial in ensuring a trouble-free energy supply through new generations of transformers and generators.

UL-recognized Kapton® and Nomex® tapes offer excellent oil compatibility, which is crucial for boosting the performance and longevity of transformers and generators. As a result, maintenance efforts in electro-mechanical applications can be minimized, and the equipment can operate at peak efficiency for longer periods.

Renewable energy sources may not be available around the clock, which creates intermittency.

Renewable electricity generation does not always align with peak demand hours, causing grid stress due to fluctuations and power peaks. Unpredictable weather events can disrupt these technologies.

The current infrastructure is mainly designed to support regional fossil fuel and nuclear plants. As a result, renewable energy often needs to be transported over long distances from the remote areas where it is produced to the regions it is consumed.

Renewable energy sources, such as solar and wind power, can be unpredictable and generate surplus energy. Efficient storage systems are needed to store excess energy during low demand and release it when demand is high.

The Importance of Energy Storage in Future Energy Supply

Sustainability is a crucial factor for economic growth, and it will continue to be an important consideration in the future.

Demand for clean energy drives sustainable technology development that will impact future energy and the environment.

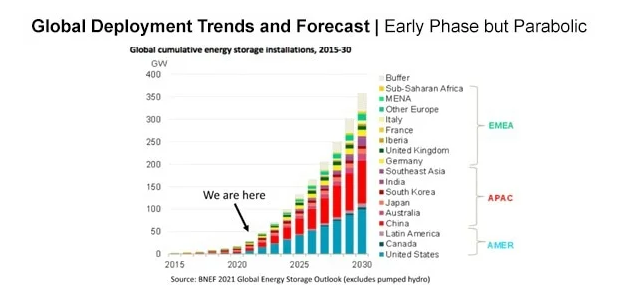

Stationary energy storage is essential in transitioning to a sustainable energy system with higher shares of renewable energy.

Energy storage has become a ubiquitous component of the electricity grid, leading to a boom in storage capacity worldwide as electricity is expected to make up half of the final energy consumption by 2050.

Efficient and Safe Energy Supply with Stationary Energy Storage

Optimized energy storage systems ensure grid stability and on-demand availability, preventing blackouts. They are essential in modern smart grids, meeting changing energy demands, such as electric mobility.

Energy storage provides flexibility and opportunities for remote areas using various technologies, including electro-mechanical, chemical, thermal, and electrochemical (batteries).

Advancements in battery technologies and their decreasing costs have enabled the growth of stationary energy storage. Improved energy density, cycle life, and safety have made batteries more efficient and reliable, while lower costs have made them more accessible.

Hydroelectric dams store bulk energy in the long term, while short-term energy storage is achieved through various technologies, such as electric batteries, flow batteries, flywheel energy storage, and supercapacitors.

These technologies offer different characteristics and are suitable for various applications, providing flexibility, stability, and reliability to the energy system.

Lithium-ion (Li-ion) batteries are the most widely used technology for grid-oriented rechargeable electrochemical battery energy storage systems (BESS). Sodium-ion batteries, although less common, are being developed as a potential alternative.

Sodium-ion batteries for BESS are a promising option due to the abundance of sodium resources but are still in the early stages of development. They have the potential as a cost-effective alternative to Li-ion batteries, with lower power density.

Lithium-ion batteries are well-established in the automotive industry, with higher energy density than sodium-ion batteries.

Lithium-ion batteries require high-end materials and thermal protection but are a good solution for the short-duration range. They have the potential for optimization in terms of energy density, safety, loading cycles, and cost.

As battery technology advances, materials are evolving to improve the energy density, cycle life, safety, and cost of Li-ion batteries.

Compression Pads That Combine Increased Loading Cycles and Energy Density

Compression pads with a low compression force deflection (CFD) curve can improve the lifetime, durability, and performance of Li-ion batteries in energy storage systems.

They distribute forces evenly, prevent internal damage, and reduce the risk of thermal runaway. Optimal pressure on cells can maximize loading cycles and extend battery life.

Micro-cellular polyurethane foams, such as Norseal® PF100 or PF47 Series, are designed for high energy density and optimal thickness.

They enable more cells to be packed into a single unit, increasing performance and allowing for the creation of battery energy storage systems with maximized energy density and minimized space requirements.

Maintaining a sealed environment for batteries is crucial to protect them from outside elements. Saint Gobain provides a range of battery pack housing options that include foam-in-place gasketing, silicone foam rubbers, butyl-coated PVC, and micro-cellular PUR foams.

Maximize Safety to Enhance Battery Pack Performance

Safety is critical in Li-ion battery-based energy storage as flammable materials are used to maximize performance.

Thermal Runaway Protection materials enhance the safety and reliability of battery modules and packs for BESS systems by providing thermal insulation, fire-blocking characteristics, and excellent compression set resistance.

The Norseal TRP Series prevents adjacent cells from experiencing exothermic reactions and stops thermal runaway propagation, protecting battery systems. This technology plays a crucial role in enhancing the safety and reliability of battery energy storage systems.

To regulate battery temperature, improve functionality, and extend battery life in Li-ion batteries, it is important to control heat. The ThermaCool® R10404 Series Thermal Interface Materials effectively remove excess heat, ensuring the safe and efficient operation of battery energy storage systems under demanding conditions.

The thermally conductive gap fillers act as heat sinks, allowing heat to flow away from batteries.

High-End Materials to Create Cost-Effective BESS Solutions

These solutions enable customers to design large BESS systems that are safe and reliable for long-term operation in harsh conditions. By reducing the risk of thermal runaway, this technology enhances the safety and efficiency of battery energy storage systems.

More cells in a battery pack can boost performance and longevity by offering higher energy storage capacity in a smaller space, though this can increase the risk of cell imbalance and failure.

This battery combination is ideal for decentralized and cost-effective energy production and storage in industrial buildings and private households with solar collectors.

Solutions, Know-How, and Capabilities for Next-Level BESS

Tailored materials cater to energy storage systems of various sizes and types by fulfilling their specific cushioning, compression, protection, and insulation needs. This supports the transition to a sustainable energy supply.

Specialized materials and expertise in high-performance battery pack development can aid in designing Li-ion BESS for stationary grid energy storage